From lipsticks to front grills:

Sprimag floor conveyors and bar coating machines

System concepts for floor conveyors and bar coating machines optimally complement the standardised module catalogue of Sprimag. Whether it’s for large or small components, and low or high-volume production, the versatile Sprimag coating machines fulfil all your different types of production requirements. In order to satisfy the continuously growing requirements on quality and production performances, being an innovative coating machine manufacturer, our goal is to recognise product and application trends at an early stage and to implement these into market and environmentally-friendly solutions for our customers.

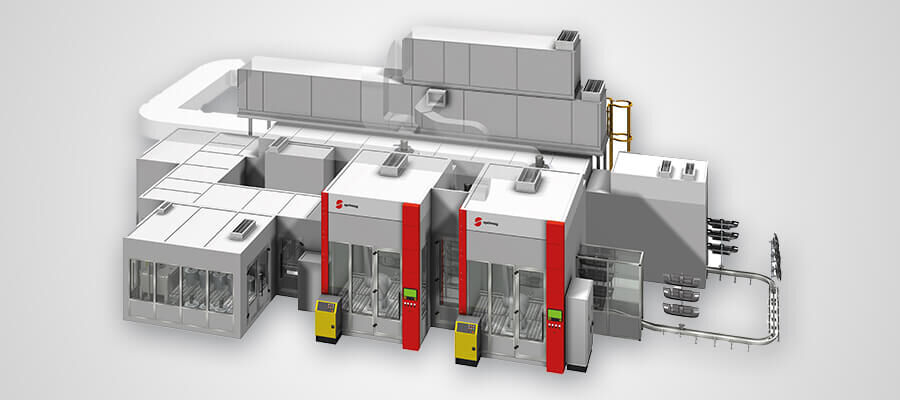

FLOOR CONVEYORS

Today, floor conveyors are indispensable when feeding larger components. A typical feature is a continuous and cycling operation. Depending on the individual requirements of the parts to be fed, Sprimag has simple single line floor conveyors as well as flexible versions such as Power & Free systems available. All process steps, from the pretreatment to evaporation and drying up to cooling can be integrated into Sprimag’s floor conveyors.

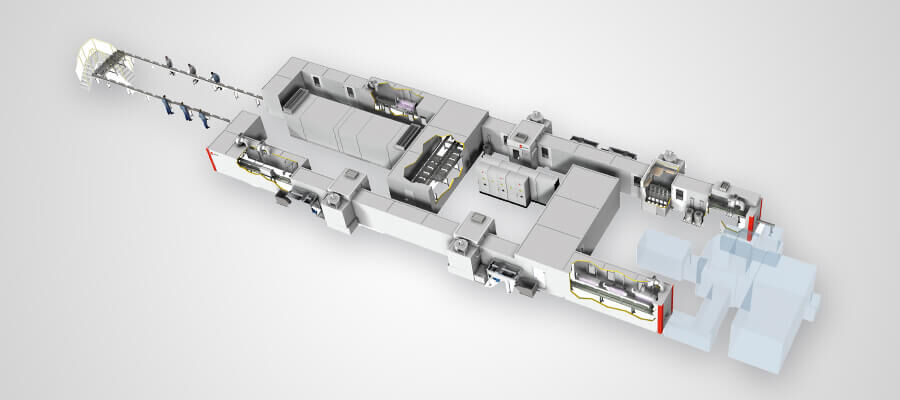

BAR COATING MACHINES

Bar coating machines are one of the most frequently used system concepts in the glass and cosmetic industries because of the high production quantities, the resulting process and conveyor speeds, and the mostly individual and discontinuous method of transportation. Several workpieces arranged lengthwise on a bar coating machine are moved discontinuously at high speed through the continuously moving coating process. The Sprimag bar coating machines can also be integrated into all process steps of the system concept, such as pretreatment, evaporation, drying and cooling without any problem.

And as the workpiece carrier can be released from the base carrier, the bar coating machine can also be used in combination with metallization/PVD processes. Within the provision of such concepts, Sprimag can already look back on many years of experience.

OPTIONS

- Pretreatment such as ionization, flaming, CO2 blasting

- Air-intake systems for filtered, conditioned air

- Sprimag 2 component / 3 component paint supply

- Dryers with UV, recirculating air, infrared

- Workpiece carrier coding with automatic allocation of the program is possible

- Paint sludge disposal systems (sludge presses, separator)