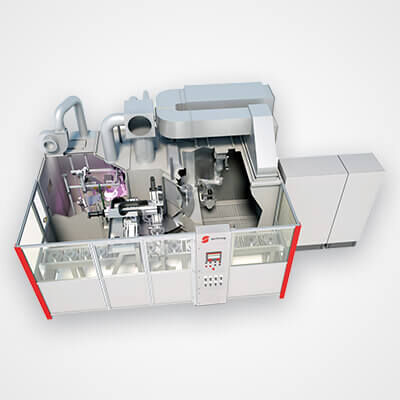

Compact Coating Solution: The Sprimag Round Table Coating Machine

The Sprimag "Round Table Coating Machine" is a robust design that has been continuously improved and updated since its inception in 1928. With a very compact footprint the coating machine is truly a stand-alone painting machine that can be customized per the particular application. It is ideal for smaller part quantities with short process times.

Optimal Coating of Rotationally Symmetrical Parts

As a rotary spindle machine it is ideal for coating rotationally symmetrical parts such as brake discs, wheel hubs, flacons or sleeves. Typical applications of the Round Table Coating Machine is coating with rubber-to-metal bonding agents or UV-paints. It is also particularly suitable for quick-drying water and solvent based paints.

Because of its small footprint, the Round Table Coating Machine is often integrated into production lines and thus also offers an economical inline solution.

- Solid, rugged machine with small footprint

- Variable number of „active” spindles – selectable within the control system

- Servo-technology for fast, reliable and exact positioning

- Operator selectable single, double or multi index operation modes possible

- Dry or wet exhaust

- Designed to handle heavy parts

OPTIONS For your Coating Machine

- Pretreatment with ionization, flame, dry ice (CO2), laser or induction

- Linear axes or coating robot for special coating applications

- Automatic masking

- Convection, infrared, UV or induction dryers

- Further spray cabin can be integrated

- And many more...