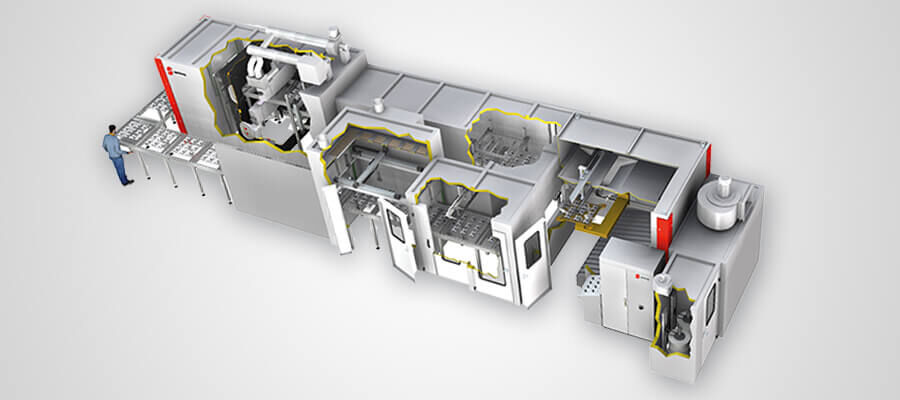

Excellent Coating of Flat Parts: Sprimag Three-axis Coating Machine

The Sprimag Three-axis Coating Machine is an extremely versatile system for coating applications with the highest quality requirements. It is suitable for coating flat parts, where a specified layer thickness must be precisely held within very tight tolerances. This may be: automotive interior parts, faceplates, pushbuttons, keyboards keys (laser paint coatings, day and night design).

Modular Expansions of the Coating Machine

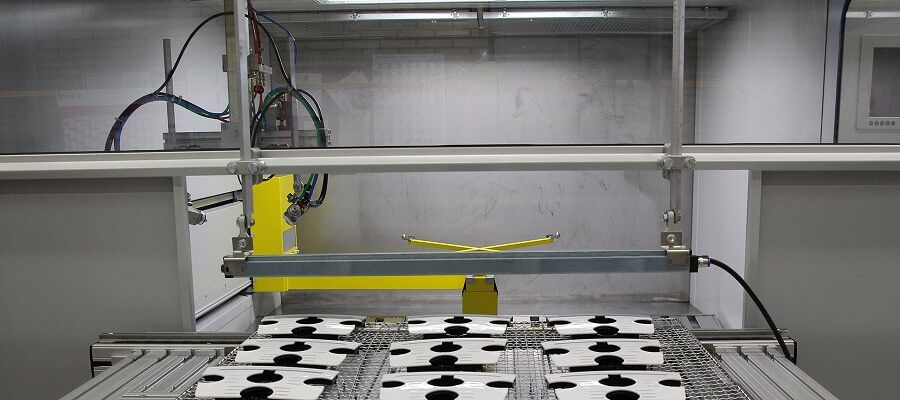

The parts are carried on a conveying axis inside the coating cell. Coating is carried out by one or several machine spray guns, which are mounted on a reciprocating axis installed transverse to the conveying direction. During the coating program, the pallet may be horizontal rotated and then recoated, hence creating a crisscross spraying pattern.

Optimal Conveyor Technology for your Spray Booth

For years, Sprimag has been successfully implementing pallet conveyor technology at its customers' sites in order to carry out highly flexible horizontal coating on plastic parts. The conveyor system consists of various elements, such as lifting and lowering stations, crossovers, conveyor sections where parts can and cannot accumulate, etc. These elements make it possible to establish a flexible material flow concept which can include bypasses, junctions and switches. The workpieces are conveyed through the coating process on a pallet which is not fixed to the conveying system. Both "stop and go" and continuous modes of operation are available in the coating system, with different process speeds.

- High quality coating of simple 3D shaped parts

- Stand-alone unit or integrated system

- Pallet size 800 x 800 mm (Other specifications on request)

OPTIONS

- Pallet encoding with automatic process flow through the system

- Pretreatment such as CO2, ionization, flame activation or plasma

- Integrated flash-off zone, dryer and cooling zone

- Different curing processes (convection, infrared, UV …)

- Air make-up system for filtered and conditioned air supply

- Sprimag 2K/3K paint supply system, completely integrated in the central control system

- Linkage of transport system with external production areas

- Waste disposal system (sludge press, centrifugal separator)

APPLICATION AREAS OF THE Three-axis Coating Machine