Piston Coating with Highest Precision:

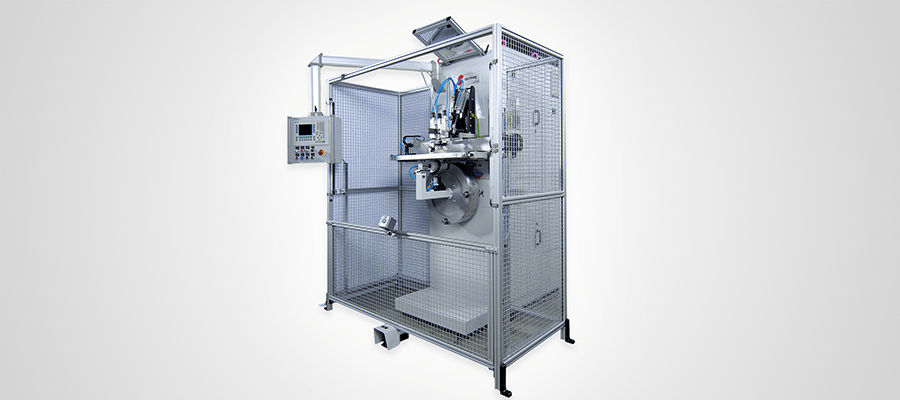

Sprimag Piston Coating Machine “Pico”

Applying low friction coatings to piston skirts was previously done using spray guns. This process has some disadvantages including significant masking, time-consuming set-up, cleaning and excessive over-spray. These shortcomings inspired Sprimag to develop a screen printing technology especially for round components without an exact circular shape: the Pico silkscreen-printing machine.

Reduced Paint Loss due to Silkscreen Printing

Silkscreen printing is an efficient method of coating with little paint loss and sharp borders. The screen serves as a mask which defines the print image. A squeegee pushes the ink through the screen as the screen moves slowly across the rotating part. The coating thickness is determined by the screen’s mesh size.

The main advantage of the Pico is the use of a distortion-free template for all diameters. With its "electronic shaft", the control interpolates the slip-free movement between screen and piston at any diameter, thus reducing the effort required to construct the screens.

Due to the compact size, the Pico silkscreen-printing machine can be easily integrated into a production line.

More information.

- 60-80 % savings compared to conventional coating technologies

- Minimum set-up times

- Precise coating with sharp borders and minimal layer thickness tolerance of ±2 µm

- Robust design and high-quality processing

- Slip-free system for precise coating of the pistons

- Tool-free adjustment

- Graphic user interface

- Standard diameter of the parts: 53 – 150 mm (other diameters on request)

- Standard height of the parts 45 – 100 mm

- Capacity up to 720 parts/h

- Integrated control cabinet in the rear oft he machine