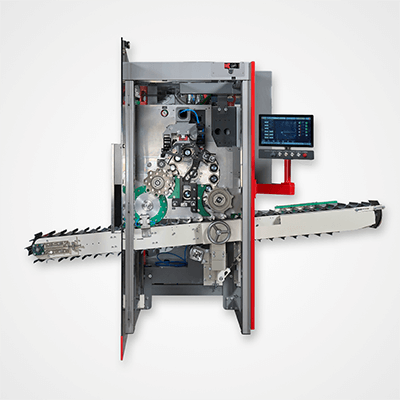

CIM-12: Camera-based end-of-line inspection for monobloc aerosol cans

Thanks to its high-end camera system the new camera inspection machine CIM-12 inspects both the entire can body as well as the neck area after the deformation process of the necking machine from above and transfers the cans to the packaging area after testing.

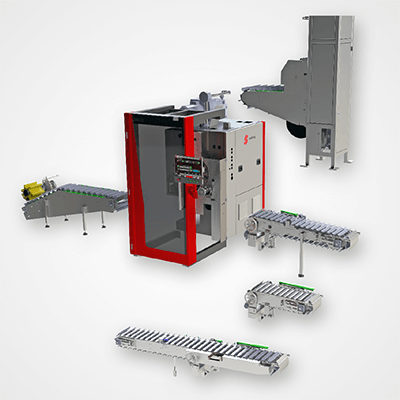

- Flexible machine concept for integration into the outfeed conveyor belt or as a stand-alone option between necking machine and packaging area

- Extremely compact footprint

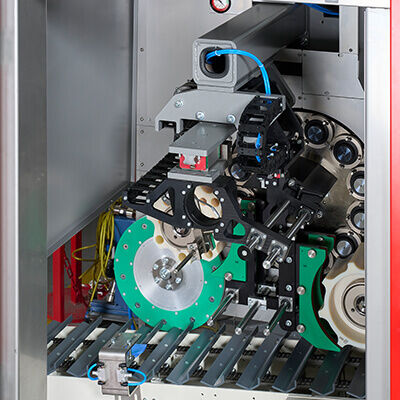

- 3 + 1 inspection systems can be integrated

- Solid mechanical-based drive concept

- (central gearbox + main drive)

The machine is designed as an open platform in terms of the integration of inspection systems and allows the use of different camera and inspection systems depending on individual requirements.

Following areas may be inspected:

- Curl and shoulder incl. print

- Full-body inspection down to the can bottom

- Print on lateral surface

- Leak detection by means of light tester

Technical Data

- Product range: Aerosol cans

- Standard diameter: Lmin 22 mm, Lmax 66 mm

- Trimmed can height: 300 mm

- Production speed: 250 cpm

- >> Datasheet for Download

Options

- Various transfer options

(infeed / outfeed / bypass belt or integration of the upstream / downstream machine) - Inspection of large cans up to Ø 80 mm

More about Camera Inspection and Aerosol Cans