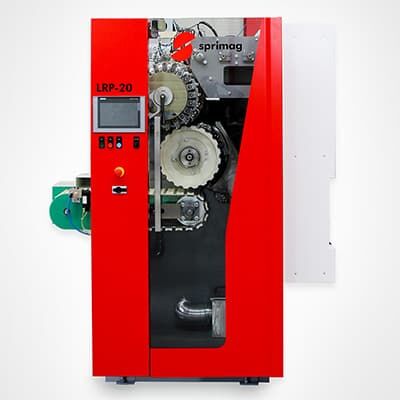

LRP-20: leak detection testing machine

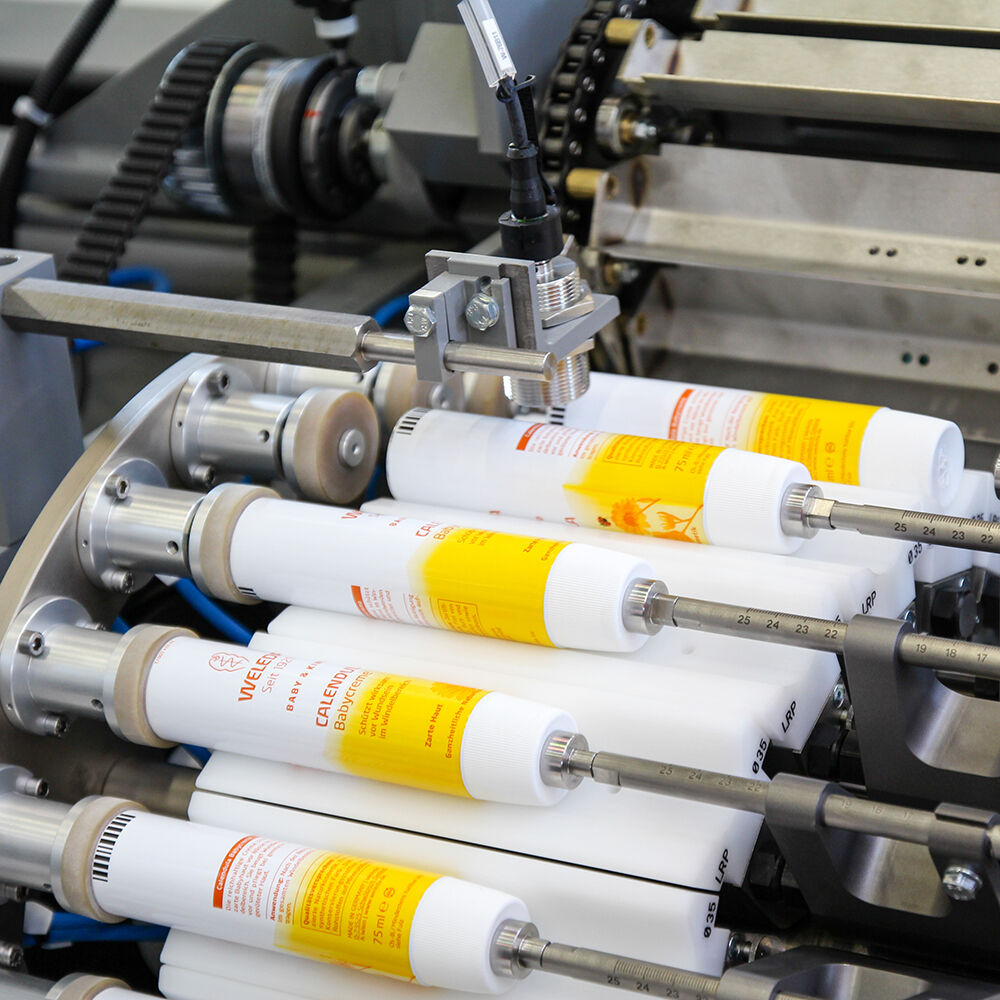

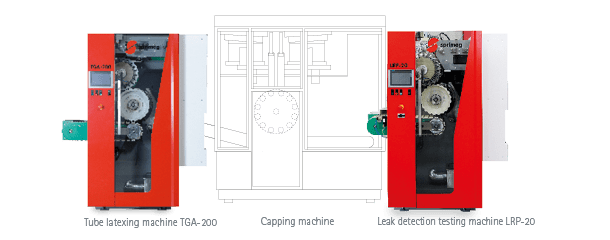

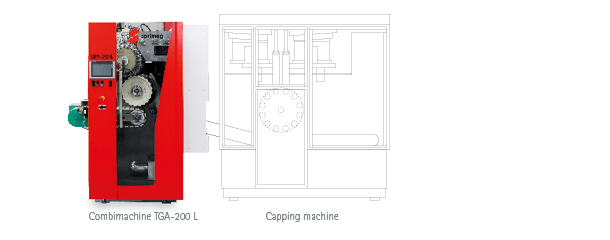

With the Sprimag leak detection testing machine LRP-20, aluminum tubes can be tested reliably for leaks and cracks. The concept of the machine is based on a modular system and can be used flexibly as LRP-20 in front or as a combimachine TGA-200L after the capping machine

With the next click you will load the video from YouTube. In this case, YouTube may set cookies which we have no influence on.

More information.

More information.

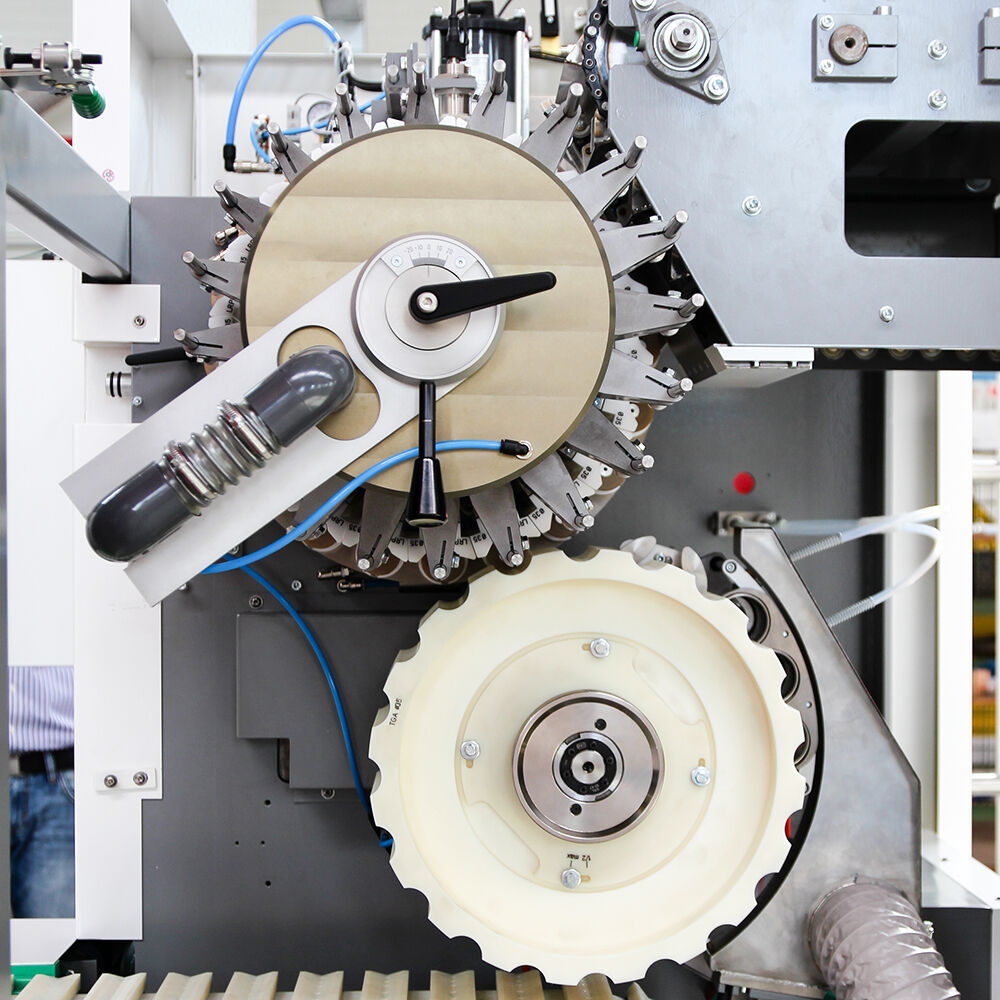

- 20 testing heads guarantee a sufficiently long cycle time

- Detects leaks reliably with a diameter starting from 0.04 mm

- Drum concept for precise positioning of the aluminum tubes

- Variable infeed and outfeed conveyor system can be adapted to any standard transfer concept

- Automatic ejection of non-okay tubes into a separate container

- Compact machine design: 2100 mm x 1700 mm x 1800 m / height x width x depth (incl. infeed and outfeed conveyor system)

- Easy accessibility to the machine interior

TECHNICAL DATA

- Product range: Aluminum tubes

- Production speed: up to 200 tpm

- Testing time: 180: 2.4 Sec, 200: 2.1 Sec.

- Standard tube diameter: Dmin 10 mm, Dmax 50 mm

- Standard tube length: Lmin 70 mm, Lmax 220 mm

- Testing heads: 20 pcs

Options

- Stand-alone option: LRP-20

- Example for integration in the production line together with the capping machine

- 2-in-1 solution as a combimachine with testing and latexing function: TGA-200L

More about leak detection and aluminum tubes