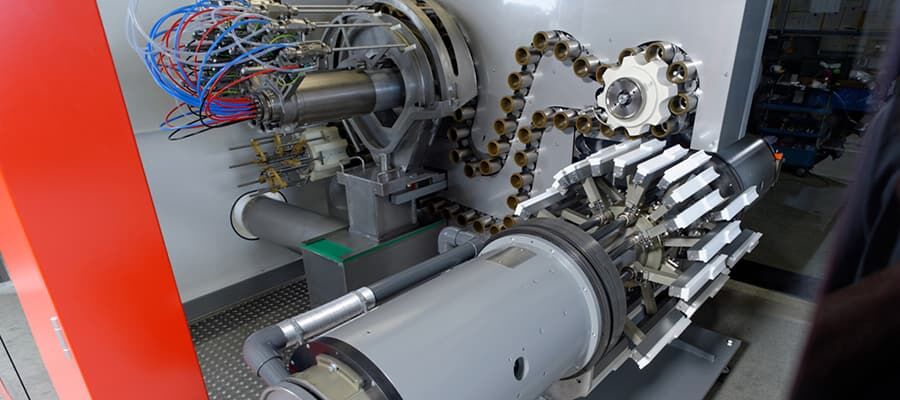

HIL-94: Functionality meets Design

The impressive features of the new internal coating machine HIL-94 for aerosol cans and bottles include high machine performance and optimal maintenance friendliness in combination with a new design. The maximum line speed of the HIL-94 is trendsetting: up to 250 cans per minute can be precisely internally coated.

- Low vibration due to solid mechanical design

- Individual vacuum circuit for machine infeed and outfeed

- Increased user comfort by direct electro-pneumatic control of the spray guns by HMI

- Shorter cleaning times by optimized exhaust performance

- Height adjustable and horizontally moveable control panel

- Combinations with different internal coating drier options (1, 2 or 3 rows)

- Manufactured in accordance with the ATEX regulations

OPTIONS

- Additional lacquer supply

- Cleaning device for spray gun extensions

- Energy optimizing system and vacuum control

- Second spray arm with full spraying equipment assembly

- Can bottom suction device

- RFID-access verification system to organize access authorizations

- Division of spray gun groups into separately controlled circuits

TECHNICAL DATA

- Product range: aerosol cans and beverage bottles

- Product diameter: Dmin 20 mm, Dmax 76 mm

- Trimmed can height: Lmin 70 mm, Lmax 280 mm

- Production speed: 250 cpm

- Spray guns/Spray process: 9/3 times

With the next click you will load the video from YouTube. In this case, YouTube may set cookies which we have no influence on.

More information.

More information.

Application Areas of the Internal Coating Machine